- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

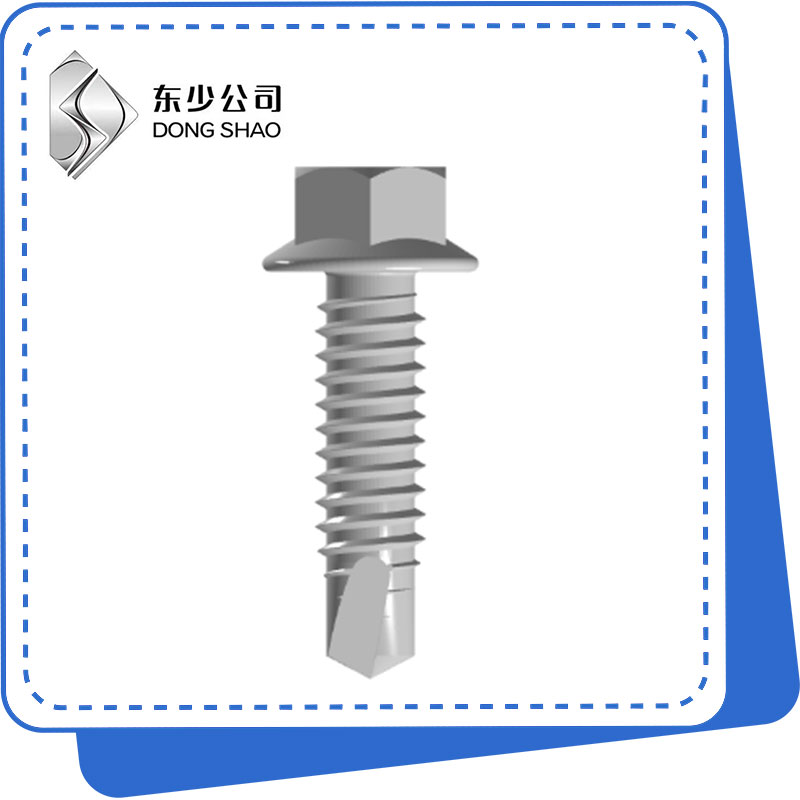

Why Are Self-Drilling Screws the Smart Choice for Modern Construction Projects?

In today's fast-paced construction and manufacturing industries, efficiency and reliability are paramount. Self-drilling screws have become one of the most essential fastening components due to their precision, strength, and time-saving installation process. Unlike traditional screws that require pre-drilling, these innovative fasteners combine drilling and fastening into a single step, streamlining work and improving productivity. This article explores the working principles, specifications, applications, and advantages of self-drilling screws, with insights from Hebei Dongshao Fastener Manufacturing Co., Ltd., a leading manufacturer in the field.

What Makes Self-Drilling Screws Different from Traditional Screws?

Self-drilling screws are unique in their design, featuring a built-in drill point at the tip that eliminates the need for pre-drilling holes. This design enables them to cut through metal, wood, or plastic surfaces directly, saving time and reducing tool wear.

They are particularly popular in construction, roofing, and metal fabrication industries where efficiency and precision are crucial. The screws also ensure a tight and secure fit, minimizing loosening or vibration over time.

At Hebei Dongshao Fastener Manufacturing Co., Ltd., each screw is engineered with strict quality standards to ensure durability, corrosion resistance, and consistent performance even under high-stress environments.

Why Choose Self-Drilling Screws from Hebei Dongshao Fastener Manufacturing Co., Ltd.?

Our Self-drilling screws are manufactured using high-quality carbon steel and stainless steel, with precise heat treatment to achieve superior hardness and strength. We also offer various surface coatings, including zinc plating, black oxide, and stainless finish, to enhance corrosion protection for outdoor or industrial use.

Our screws are designed with sharp threads and accurate points, ensuring fast penetration and secure grip in multiple materials.

Product Specifications

| Parameter | Specification Details |

|---|---|

| Product Name | Self-Drilling Screws |

| Material | Carbon Steel / Stainless Steel (304, 316) |

| Head Type | Hex Washer Head / Pan Head / Flat Head / Truss Head |

| Drive Type | Phillips / Hex / Torx |

| Surface Finish | Zinc-Plated, Black Oxide, Nickel-Plated, Ruspert, Stainless Finish |

| Drill Point Type | TEK 1–5 (depending on drilling depth) |

| Thread Type | Fine / Coarse / Twin Thread |

| Diameter Range | M3.5 – M6.3 (or customized) |

| Length Range | 10mm – 150mm |

| Tensile Strength | 800–1200 N/mm² (depending on material) |

| Application Fields | Roofing, Metal Framing, HVAC, Construction, Automotive, Furniture Assembly |

Every Self-drilling screw produced by Hebei Dongshao Fastener Manufacturing Co., Ltd. undergoes strict quality control, including hardness testing, torque testing, and corrosion resistance evaluation, to ensure reliability in demanding applications.

How Do Self-Drilling Screws Work?

The working principle of self-drilling screws is simple yet effective. The screw's tip acts as a drill bit that pierces the surface, creating its own pilot hole. As the screw rotates, its threads engage with the material, securing the components tightly together.

This dual-function design allows for quick and clean installations, significantly reducing labor time and eliminating the need for separate drilling tools. It also ensures precise alignment, especially when joining thin metal sheets or structural frames.

What Are the Main Applications of Self-Drilling Screws?

Self-drilling screws are widely used across multiple industries for their convenience and performance:

-

Construction: Ideal for fastening steel and aluminum frames, roofing sheets, and wall panels.

-

Automotive: Used in assembly lines for securing components with precision.

-

Furniture Manufacturing: Ensures stable connections without splitting the wood.

-

HVAC Systems: Used in ducting and ventilation installations due to their vibration resistance.

-

Electrical Equipment: Perfect for fixing control panels or enclosures.

Thanks to their adaptability and strength, Self-drilling screws are the go-to choice for both professional builders and DIY enthusiasts.

What Are the Benefits of Using Self-Drilling Screws?

-

Time Efficiency: No pre-drilling required, reducing installation time by up to 50%.

-

Cost Reduction: Fewer tools and less labor needed.

-

Durability: High tensile strength and corrosion resistance ensure long-term reliability.

-

Versatility: Suitable for metals, plastics, and wood.

-

Secure Fastening: Designed to prevent loosening from vibration or thermal expansion.

These advantages make them indispensable in modern construction and manufacturing processes.

How to Select the Right Self-Drilling Screw for Your Project?

Choosing the correct screw depends on several factors such as the material thickness, environment, and load requirements.

-

For thin steel sheets (up to 2mm): Use TEK 1–3 drill points.

-

For thicker metal (up to 12mm): Choose TEK 4–5 points.

-

For outdoor applications: Opt for stainless steel or Ruspert-coated screws.

-

For wood or soft materials: Coarse threads work best.

Hebei Dongshao Fastener Manufacturing Co., Ltd. provides customized options based on your project needs, ensuring optimal fastening performance and longevity.

FAQ: Common Questions About Self-Drilling Screws

Q1: What materials can Self-drilling Screws be used on?

A1: Self-drilling screws can be used on metals (steel, aluminum), plastics, and wood. Their integrated drill point makes them ideal for thin to medium-thickness materials without pre-drilling.

Q2: Are Self-drilling Screws rust-resistant?

A2: Yes. At Hebei Dongshao Fastener Manufacturing Co., Ltd., we offer various corrosion-resistant finishes such as zinc-plating, Ruspert, and stainless steel options that extend product life even in outdoor or humid environments.

Q3: How do I know which drill point type to choose?

A3: The drill point type (TEK 1–5) determines how thick the material can be drilled. For instance, TEK 1 and 2 are for thin sheets, while TEK 4 and 5 are suitable for structural steel applications up to 12mm thick.

Q4: Can Self-drilling Screws replace regular screws in all applications?

A4: Not always. While self-drilling screws are versatile, they are best suited for materials where drilling and fastening can be combined. For dense hardwoods or reinforced concrete, specialized fasteners are recommended.

Contact Us

With over a decade of experience in fastener manufacturing, Hebei Dongshao Fastener Manufacturing Co., Ltd. has built a strong reputation for quality, reliability, and customer satisfaction. Our factory employs advanced machinery, precision inspection tools, and a professional R&D team to ensure every product meets global standards such as ISO and DIN.

We are committed to delivering premium fastening solutions that enhance efficiency, safety, and performance across industries.

If you are looking for a trusted partner for Self-drilling screws or customized fastening solutions, Hebei Dongshao Fastener Manufacturing Co., Ltd. is here to help.