- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

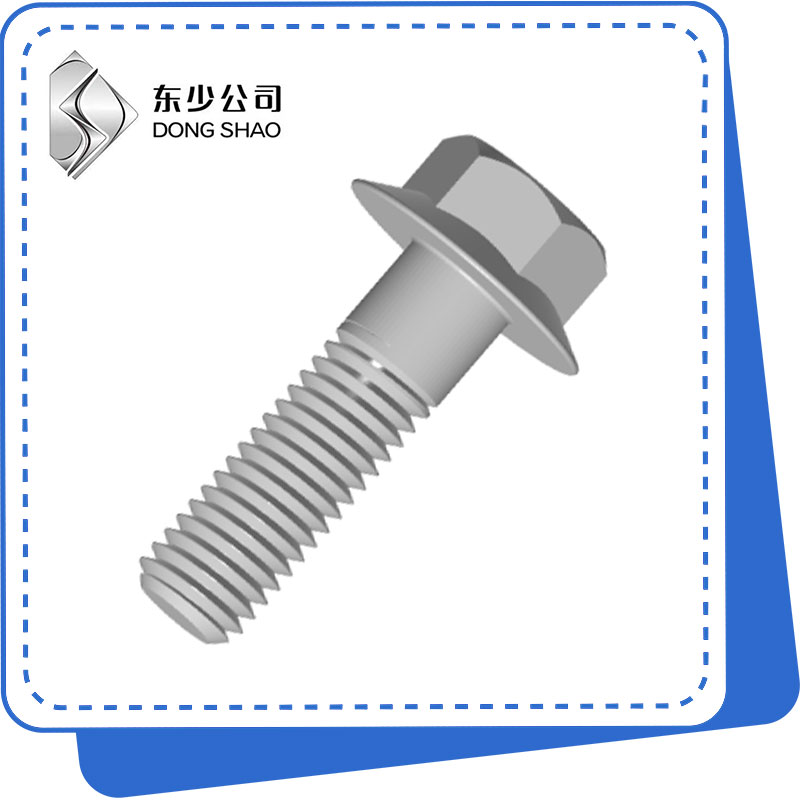

Why Choose Hexagon Head Bolts with Flange for Industrial Applications?

2025-12-17

Hexagon head bolts with flange are a crucial component in modern mechanical and structural engineering. Designed to provide both secure fastening and load distribution, these bolts have become a standard in industries ranging from automotive to construction. Unlike standard hex bolts, the integrated flange under the head acts like a washer, reducing the need for separate components and ensuring a more even distribution of pressure over the material surface.

In this article, we'll explore the features, specifications, advantages, and applications of Hexagon Head Bolts with Flange. We will also answer frequently asked questions to help engineers, procurement managers, and DIY enthusiasts make informed decisions.

How Do Hexagon Head Bolts with Flange Differ from Standard Hex Bolts?

The main difference between a standard hex bolt and a hexagon head bolt with flange is the presence of the flange. This flange:

-

Acts as a built-in washer

-

Provides greater bearing surface

-

Reduces stress concentration

-

Minimizes loosening due to vibrations

Key Advantages Over Standard Hex Bolts:

-

Improved Load Distribution: The flange spreads the load more evenly, preventing damage to the material surface.

-

Enhanced Vibration Resistance: Ideal for automotive or machinery applications where vibration is common.

-

Reduced Assembly Time: No separate washer is needed, saving both time and cost.

-

Better Corrosion Resistance: Often paired with coatings or stainless steel to withstand harsh environments.

What Are the Typical Specifications of Hexagon Head Bolts with Flange?

Hexagon Head Bolts with Flange are manufactured according to international standards, ensuring compatibility with most mechanical and structural components. Below is a table illustrating typical product specifications:

| Specification | Details |

|---|---|

| Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Thread Standard | Metric (M6–M30), UNC, UNF |

| Length | 20mm – 200mm (customizable) |

| Head Type | Hexagon with integrated flange |

| Surface Finish | Zinc-plated, Black Oxide, Galvanized, Plain |

| Grade | 4.8, 8.8, 10.9 (metric); ASTM A325/A490 |

| Application | Automotive, Construction, Machinery, Industrial Equipment |

| Corrosion Resistance | High, depending on material and coating |

| Torque Specifications | Varies by size and material; follows ISO and ASTM recommendations |

These parameters make Hexagon Head Bolts with Flange highly versatile, suitable for both heavy-duty industrial projects and everyday assembly tasks.

Why Are Hexagon Head Bolts with Flange Preferred in Automotive and Industrial Applications?

In automotive and industrial settings, equipment experiences constant stress and vibration. Hexagon Head Bolts with Flange provide:

-

High clamping force to secure components

-

Resistance to loosening, especially in engines and machinery

-

Simplified assembly, reducing maintenance time

For example, in automotive engines, flange bolts are commonly used to secure cylinder heads. The flange distributes clamping pressure evenly across the surface, preventing warping or material damage. In machinery, these bolts maintain structural integrity under continuous vibrations.

How Should Hexagon Head Bolts with Flange Be Installed for Optimal Performance?

Proper installation is key to maximizing the performance of these bolts. Consider the following steps:

-

Select the Right Material and Grade: Ensure compatibility with environmental conditions and load requirements.

-

Torque Correctly: Use a torque wrench to apply the recommended torque. Over-tightening can strip threads or deform materials; under-tightening may lead to loosening.

-

Check Surface Conditions: Ensure that the contact surface is clean and free from rust or debris.

-

Lubrication: In some cases, anti-seize or lubricant may be applied to improve torque accuracy and prevent galling.

Following these installation guidelines ensures long-term durability and performance, minimizing maintenance and failure risks.

What Are the Common Sizes and Grades Available?

Hexagon Head Bolts with Flange come in a wide range of sizes and grades to meet different engineering requirements:

-

Sizes: M6 to M30 for metric, 1/4" to 1-1/4" for imperial

-

Grades:

-

4.8: General purpose applications

-

8.8: High-strength structural applications

-

10.9: Heavy-duty industrial machinery

-

-

Length: Customized based on project needs

This wide range allows engineers and procurement teams to select bolts precisely according to mechanical design standards and load requirements.

Hexagon Head Bolts with Flange vs. Flanged Hex Nuts: Which Should You Choose?

While hexagon head bolts with flange have a built-in washer, flanged hex nuts provide similar load distribution but are used in conjunction with standard bolts. Choosing between them depends on your application:

| Feature | Hexagon Head Bolt with Flange | Flanged Hex Nut |

|---|---|---|

| Integrated Washer | Yes | Yes |

| Ease of Assembly | Higher (no separate washer needed) | Moderate (requires compatible bolt) |

| Vibration Resistance | Excellent | Moderate |

| Cost Efficiency | Higher initial cost but reduces assembly | Lower initial cost, more parts required |

| Typical Use Case | Engines, machinery, structural components | Bolt-nut assemblies for general fastening |

In most industrial applications, hexagon head bolts with flange are preferred due to their integrated design and enhanced reliability.

FAQ: Hexagon Head Bolts with Flange

Q1: What is a hexagon head bolt with flange used for?

A1: Hexagon head bolts with flange are primarily used in applications requiring high clamping force, vibration resistance, and even load distribution. They are widely used in automotive engines, machinery, construction, and structural frameworks.

Q2: How do I choose the right grade for my project?

A2: Select a grade based on strength requirements and material compatibility. For light-duty projects, grade 4.8 is sufficient. For heavy machinery, grades 8.8 or 10.9 are recommended. Always consider environmental conditions, such as corrosion or temperature extremes.

Q3: Can hexagon head bolts with flange replace standard bolts and washers?

A3: Yes. The built-in flange serves as an integrated washer, eliminating the need for a separate washer. This simplifies assembly, saves time, and reduces the number of components required.

Q4: What materials are available for hexagon head bolts with flange?

A4: They are available in carbon steel, stainless steel, and alloy steel. Surface treatments like zinc plating, black oxide, and galvanization enhance corrosion resistance for different environmental conditions.

Conclusion

Hexagon Head Bolts with Flange are a reliable, versatile, and essential fastener in modern industry. Their unique design provides better load distribution, improved vibration resistance, and simplified assembly compared to standard bolts. With various sizes, grades, and materials available, they meet the diverse requirements of automotive, industrial, and structural applications.

For high-quality hexagon head bolts with flange and professional consultation, contact Hebei Dongshao Fastener Manufacturing Co.ltd. Their expertise ensures the right solution for every project, from heavy machinery to precise industrial components.