- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Choose the Right Self-drilling Screws for Your Projects?

2025-12-30

Abstract: Self-drilling screws are widely used in construction, manufacturing, and DIY projects for their efficiency and ease of use. This comprehensive guide explores different types of self-drilling screws, their specifications, installation methods, common challenges, and answers frequently asked questions to ensure optimal performance for various applications.

Table of Contents

- 1. Understanding Self-drilling Screws

- 2. Key Specifications and Selection Criteria

- 3. Installation Techniques and Best Practices

- 4. Common Questions and Expert Advice

1. Understanding Self-drilling Screws

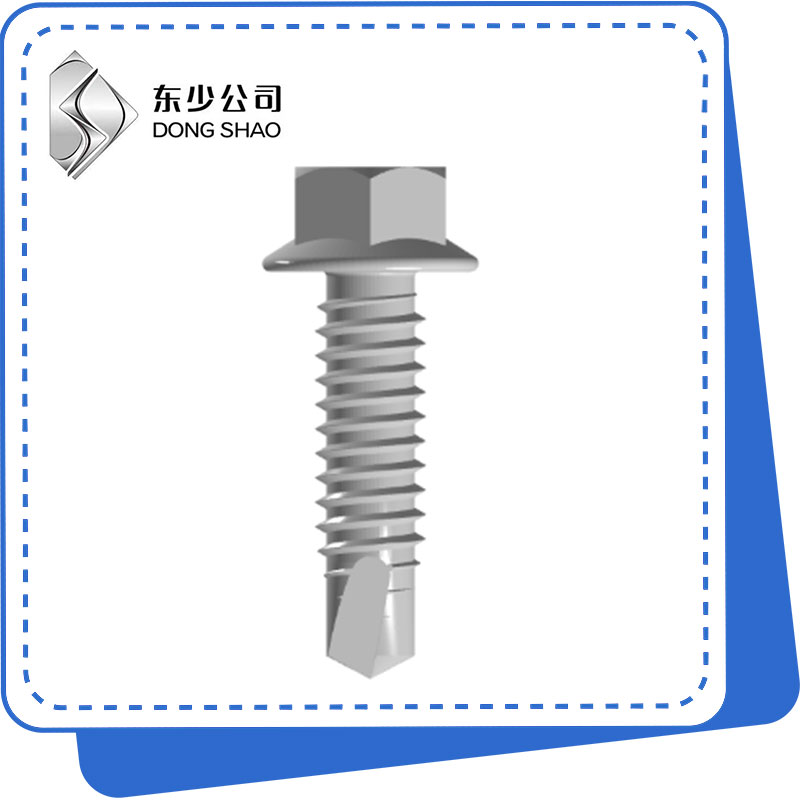

Self-drilling screws are specialized fasteners designed to drill their own hole into materials such as metal, wood, or composite structures without the need for pre-drilling. These screws feature a sharp, drill-shaped tip that eliminates the need for pilot holes, streamlining the assembly process. Their unique design reduces labor time and ensures a secure connection, making them an essential component for professional and DIY projects alike.

The core focus of this section is to introduce the types of self-drilling screws and explain their practical applications. Typically, these screws are classified based on material compatibility, head type, coating, and thread design, each catering to different project requirements.

2. Key Specifications and Selection Criteria

Choosing the correct self-drilling screw requires careful consideration of parameters such as size, material, coating, and drilling capacity. Below is a professional table outlining key product specifications:

| Parameter | Description |

|---|---|

| Material | Stainless Steel, Carbon Steel, Alloy Steel |

| Head Type | Pan Head, Hex Washer, Flat Head, Truss Head |

| Thread Type | Fine, Coarse, Partially Threaded, Fully Threaded |

| Drill Point Type | Type B, Type AB, Multi-purpose drill tip |

| Coating | Zinc Plated, Galvanized, Black Phosphate |

| Diameter | M3 to M12 (Metric), #6 to #1/2" (Imperial) |

| Length | 12mm to 150mm |

When selecting a self-drilling screw, users must assess the material being fastened, required load-bearing capacity, environmental conditions (corrosion, humidity), and compatibility with existing tools and equipment.

3. Installation Techniques and Best Practices

Proper installation of self-drilling screws is essential for structural integrity and long-term durability. The following points summarize key best practices:

- Drill Speed: Use moderate drill speeds to prevent overheating and material damage.

- Torque Settings: Adjust the torque based on material thickness and screw size to avoid stripping threads.

- Alignment: Ensure screws are perpendicular to the surface for a secure fit and uniform load distribution.

- Pre-cleaning: Remove debris and rust from surfaces to enhance screw penetration and holding strength.

- Tool Compatibility: Use high-quality electric drills or screw guns compatible with self-drilling screws to improve efficiency.

Additionally, awareness of environmental factors like temperature and moisture is important. For outdoor applications, coated or stainless steel screws are recommended to prevent corrosion.

4. Common Questions and Expert Advice

Q1: How do self-drilling screws differ from standard screws?

A1: Unlike standard screws, self-drilling screws have a built-in drill tip that enables them to penetrate materials without pre-drilling a pilot hole. This reduces installation time and simplifies assembly, especially for metal and composite applications.

Q2: Can self-drilling screws be used on thick metal sheets?

A2: Yes, but the drill point type and screw diameter must match the material thickness. For sheets thicker than 6mm, screws with a Type AB or specialized multi-purpose drill tip are recommended to ensure complete penetration without bending or breaking.

Q3: What coatings are best for corrosion resistance?

A3: Zinc plating provides moderate corrosion protection, while galvanization or stainless steel material offers superior resistance in outdoor or high-humidity environments. The choice depends on the application and exposure conditions.

Q4: How to prevent stripping or over-tightening?

A4: Use a torque-controlled drill or driver set to the screw manufacturer's recommended settings. Always align the screw perpendicular to the work surface and avoid excessive speed during drilling.

Q5: What is the ideal screw spacing for metal assembly?

A5: Screw spacing typically ranges from 6 to 12 inches for light metal panels and 4 to 6 inches for heavier load-bearing structures. Proper spacing ensures optimal load distribution and minimizes material stress.

Self-drilling screws are indispensable tools for modern construction and industrial applications due to their efficiency and reliability. Brands like DONGSHAO offer high-quality self-drilling screws with precise specifications to meet diverse project requirements. For more detailed inquiries or custom solutions, contact us to discuss options and receive professional guidance.