- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What are the differences between round washers and square washers?

2025-04-09

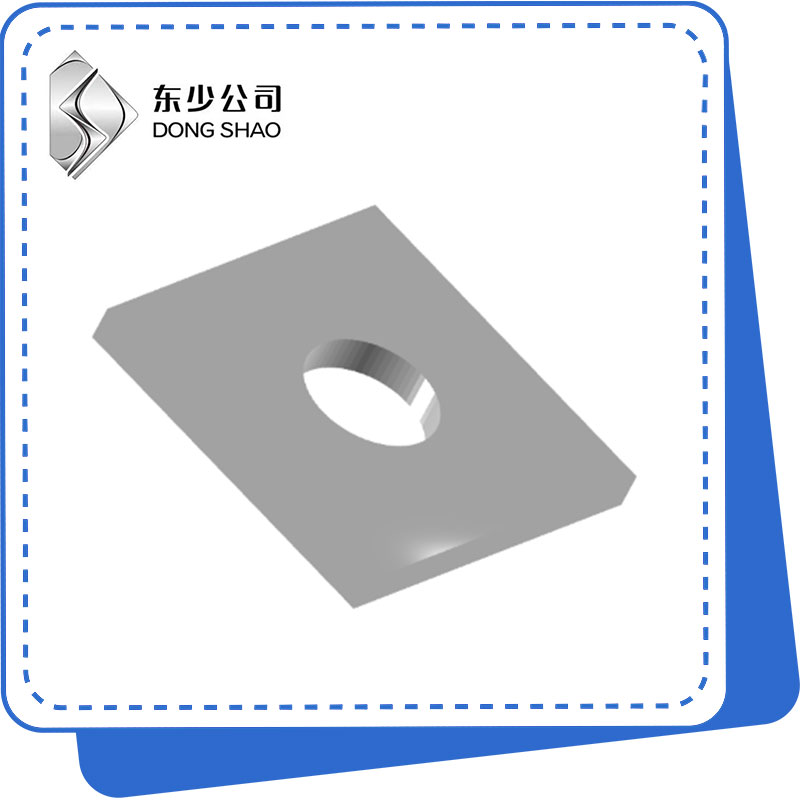

The main differences between round washers and square washers are in shape and application scenarios.

1. Shape differences

Round washers are usually round, which makes them more convenient to install and disassemble, and are suitable for occasions that require frequent installation and disassembly. Square washers are square or rectangular in shape, which makes them more effective in filling the gaps between square parts.

2. Application scenario differences

Round washers are widely used in machinery, electronics, aviation and other fields due to the versatility of their shapes. They are suitable for various equipment and components that require high precision and large temperature changes. Square washers are mainly used in industries such as petroleum, chemical, papermaking, and hemodialysis, and are suitable for occasions that require high pressure, low temperature, and corrosion resistance.

3. Material and function differences

Round washers, common materials include stainless steel and carbon steel, which are low-cost and easy to install, and are suitable for parts that are frequently installed and disassembled.

Square washers are usually made of multiple layers of different materials, such as copper, steel, etc. They have higher pressure resistance and corrosion resistance and are suitable for high pressure and special environments.